Davis Controls offers quality solutions, from a strong and balanced portfolio of world class products, to all sectors of the Canadian Process Industry, including Oil & Gas, Chemical & Petrochemical, Mining, Water & Wastewater treatment, Power Generation, Pharmaceutical and Food & Beverage processing.

Davis Controls also provides a comprehensive range of products for the manufacturing community, particularly Automotive and related industries, Packaging Machinery, Food and Beverage equipment, System Integration, Renewable Energy and of course, the sector where it all started in 1933, Boiler Controls.

Industrial Filtration

For industrial applications including Coalescing Compressed Air Filters, Sample Filters, Vacuum Pump Inlet and Exhaust Filters, High-Efficiency Liquid Filters, Filters for Hospital Applications, Natural Gas Filters, 0.01 Micron Membrane Filters, Steam and Sterile Air Filters for the Food Industry, Nitrogen Gas Generation Systems and Compressed Air Dryers, serving a wide range of industries from manufacturing to transportation; from life sciences to food and beverage.

Manufactures and distributes a comprehensive line of high-performance lubricants that far exceed conventional lubricants in various industrial and automotive applications. By significantly reducing downtime and maintenance costs, LE lubricants are also cost-effective, returning the initial price of the lubricant many times over.

LE’s Enhanced lubricants are made of highly refined or synthetic base oils as well as the following proprietary additives, which LE developed for exclusive use in its lubricants.

- Almasol® solid wear-reducing additive can withstand extremely heavy loads, chemical attacks and temperatures up to 1,900°F (1,038°C). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances.

- Monolec® liquid wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing film strength without affecting clearances.

- Duolec® dual-acting additive imparts synergistic properties to lubricants, providing both wear-reducing and extreme pressure protection. It increases film strength and is temperature-activated to provide a protective layer.

- Quinplex® impact-resistant additive contributes to outstanding water resistance, tackiness and mechanical stability, and helps to form a barrier against corrosion.

LE’s INDUSTRIAL GREASES

General purpose bearing grease to extreme pressure grease

Lubrication Engineers offers a full line of high-performance industrial greases. The LE grease line includes technologically advanced, highly versatile, general purpose, multifunctional, and extreme pressure (EP) varieties, all of which outperform conventional greases. LE’s industrial greases are formulated with various thickener types, including lithium complex, calcium sulfonate, clay (bentone), and polyurea; they come in a range of NLGI grades.

Features of LE greases, which vary depending on the type of grease, include exceptional load-carrying ability, high dropping point, low evaporation rate, low oil separation and mechanical stability. Features such as these make LE greases effective for various industrial and fleet applications, including high-temperature and high-moisture operations and extended service under extreme conditions.

LE also supplies food-grade greases that meet NSF H1 requirements for incidental food contact and are certified Kosher Pareve by the Orthodox Union and Halal by INFANCA.

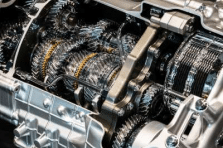

High-performance gear oil for industrial gearbox applications

Industrial gearboxes are expected to perform under high heat and heavy loads; and in environments often contaminated with dirt, process debris and water. Without adequate protection, gears will wear prematurely. Parts will need to be replaced more frequently, change oil more frequently, and worst of all, you’ll experience equipment downtime. To combat difficult conditions, LE offers an array of lubricants specially formulated for enclosed industrial gearbox applications.

Turbine Oils

LE offers turbine oil formulations for all types of turbines. Lubrication Engineers has created unique blends of gas turbine oil, steam turbine oil and hydroelectric turbine oil to protect the parts of even the most high-maintenance machines. Whether your business relies on mainline / baseload turbines or peaking turbines, LE’s premium turbine oils will inject new life into your equipment relieving it of excessive temperatures and enabling it to bear heavy loads with greater ease. LE turbine oils are available for units driven with or without reduction gears in a variety of ISO viscosity grades ISO 32, ISO 46 and ISO 68.

In addition, LE’s Low Tox® Turbine Oils feature low ecotoxicity for environmentally sensitive applications.

Hydraulic Oils for Mobile & Stationary Applications

It’s no industry secret: One of the best ways to run your hydraulic systems smoothly is to use the right hydraulic fluid. Lubrication Engineers offers a full line of multifunctional hydraulic oils, including several 100% synthetic formulations, all of which outperform conventional hydraulic fluids. They provide superior rust prevention, water separation ability, high film strength and excellent handling under extreme pressure. They ensure a smooth transition of power and protect metal surfaces from corrosion.

Industrial Oils

LE’s industrial oils work for countless applications

Lubrication Engineers’ large selection of industrial oils are well-suited for a vast array of uses, including long-service-life applications, high and low-temperature applications, applications with the possibility of incidental food contact and outdoor applications in marine environments and other areas where environmental concerns require the use of a very low-toxicity lubricant.

LE industrial oils are available in a wide range of ISO grades, with viscosities to meet any application requirement.

Most of our industrial oils contain at least one of LE’s proprietary additives to improve performance, including:

Monolec®, a wear-reducing additive that creates a single molecular lubricating film on metal surfaces

Quinplex®, an impact-resistant additive that helps to form a barrier against corrosion

Duolec®, a dual-acting additive that imparts synergistic properties to lubricants, providing both wear-reducing and extreme pressure protection

Premium Engine Oils for Diesel and Gasoline Engines

The technology exists to build high-performance engine oils that can withstand conditions and rigours for diesel trucks, passenger cars, light-duty trucks and stationary engines. Typically, engine oils are made up of 70 to 90% base oil and 10 to 30% additives. Lubrication Engineers uses premium quality base oil and best-in-class additive technology to formulate engine oils that maintain their viscosity, keep engine wear to a minimum, and help ensure dependability.

LE engine oils are formulated to meet the needs of our industrial customers and in most cases easily exceed the Automotive Performance Institute (API) specifications for performance.

Synthetic Lubricants

At Lubrication Engineers, we know that non-synthetic lubricants aren’t always the best lubricants for the job. In applications with extremely high or extremely low temperatures or very heavy loads, synthetic lubricants may overcome the challenges better than non-synthetic lubricants. For example, synthetic gear oil would provide exceptional protection in heavily loaded gearboxes exposed to high and low-temperature extremes.

Another example is a synthetic engine oil or synthetic motor oil, which would provide better viscosity stability in extreme temperature conditions.

The performance advantages offered by synthetic oils and synthetic greases vary by product, but they include improved thermal stability, improved oxidation resistance, a high viscosity index, improved low temperature properties, lower evaporation losses, reduced flammability and a lower tendency to form residues.

LE’s synthetic oil and synthetic grease varieties contain special additives that further enhance their performance. Depending on the particular lubricant and what LE formulated it to do, these additives include one or more of the following:

Monolec® – LE’s exclusive wear-reducing additive creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances. Monolec® allows opposing surfaces to slide by one another, greatly reducing friction, heat and wear.

Almasol® – LE’s exclusive solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and extremely high temperatures. It is attracted to metal surfaces, forming a microscopic layer without building on itself or affecting clearances. Almasol® minimizes metal-to-metal contact and the resulting friction, heat and wear.

Quinplex® – LE’s exclusive impact-resistant additive helps to form a barrier against corrosion and enables outstanding water resistance, tackiness and enhanced mechanical stability.

Open Gear Lubricants

Grinding, pulverizing, and breaking open gears can take a beating

Large open gears take a severe beating daily. Challenging conditions include outdoor environment, extended service operation, dust, silica, water, extreme heat and extreme pressures. Open gear lubricants must be specially formulated to keep equipment operating at maximum efficiency.

Whether you operate a ball mill, rod mill, breaker mill, or kiln, Lubrication Engineers’ Pyroshield® line of heavy-duty synthetic open gear lubricants can help protect your valuable equipment and keep it running harder and lasting longer. If you are interested in making your large open gears last longer, lowering the amount of lubricant you use, and reducing overall maintenance expenditures, then we have the solutions for you.

Wire Rope Lubricants

Proper lubrication of your wire rope, chain and cable can safely extend its operational life regardless of application. Cranes, elevators, shovels, drilling rigs, suspension bridges and draglines are some of the many applications that use wire rope, chain or cable to perform work such as pulling, dragging or hoisting. These applications often are exposed to harsh environmental conditions including extreme weather. Lubrication Engineers can help your wire rope, chain and cable last longer and operate safely by implementing a lubricant reliability program and recommending the right lubricants for the job.

Fuel Treatments for Diesel & Gasoline Engines

With the high cost of fuel and the need to get every last mile of performance out of your engines, LE’s fuel conditioners are a simple solution for improving engine performance and improving fuel economy. These gasoline and diesel fuel treatments have been formulated for use in heavy-duty industrial fleet applications. Whether you operate trucks, buses, farm vehicles, construction equipment, marine engines, or even mowers and chainsaws, our fuel treatments help you maximize engine performance and save on fuel costs – making you greener in the process.

Full Torque is a cetane-boosted, detergent-containing fuel additive formulation that increases power, improves fuel economy, reduces emissions, and provides smoother performance year-round in diesel engines. Full Torque’s cetane booster increases a fuel’s cetane number up to three numbers, resulting in faster ignition time, more power, easier starts and less smoke at startup. This hard-working diesel fuel conditioner is also loaded with special detergents that keep injector systems clean and working at maximum performance, as well as ingredients that protect against wear, water and corrosion. Full Torque has been formulated to work with today’s biofuels, ultra low sulfur diesel (ULSD) fuels, and renewable diesel fuels. It also works with today’s high pressure common rail systems.

Air Compressor Lubricants

Lubrication is critical to efficient air compressor operation

Most factories and manufacturing facilities use compressed air systems for a variety of applications, and keeping these air compressors running is critical to keeping the entire operation running. Nearly all air compressors require a form of lubricant to cool seal or lubricate internal components.

Proper lubrication will ensure that your equipment will continue operating, and the plant will avoid costly downtime and repairs. Proper lubrication also will help air compressors run cooler and consume less electrical energy. It is simple: reduced friction = reduced heat = reduced energy consumption. Compressed air systems in most manufacturing plants consume a majority of the daily power requirements, so if you are looking for a continuous improvement project, reducing energy costs through better lubricant practices is a sure winner.

Transmission Fluids

LE’s versatile transmission fluids keep fleets running

The purpose of a transmission fluid is to cool and lubricate, ensuring the smooth performance of your vehicle. The quality of your transmission fluid is especially important in extreme driving conditions such as heavy loads, steep terrain, continuous operation and lots of starts and stops.

Known worldwide for its heavy-duty, high-performance transmission fluids, LE works with small and large customers operating fleets of on- and off-road vehicles and mobile equipment. These customers depend on LE’s transmission fluids to protect their valuable mobile assets. Together, LE transmission fluids and engine oils will help any size operation keep its fleet running and avoid costly downtime and repairs.

Oven Chain Lubricants

Keep ovens working with superior oven chain lubricants

Process ovens in food processing plants and other manufacturing facilities are vital to production output, but keeping them properly lubricated can be difficult. Extreme temperatures, continuous operation and – in some cases – dirty operating conditions are typical challenges.

Offering several high-performance lubricant formulations, Lubrication Engineers has helped companies worldwide with their process oven lubrication needs. If you are interested in creating more uptime for your operation, let LE’s experienced and certified consultants help you overcome the challenges of oven chain lubrication.

Aerosol Lubricants

Heavy-duty industrial lubricants in convenient aerosol cans

If you need a small amount of lubrication in specific areas or just want to give your operators additional flexibility for handling lubrication problems, Lubrication Engineers offers several of its great industrial lubricants in easy-to-use convenient aerosol cans These are the same formulations used in our non-aerosol versions. LE’s aerosol lubricant line includes a variety of options to take care of nearly any industrial or residential lubricant application, including:

- Extreme-condition synthetic lubricants

- Penetrating lubricants

- Wire rope, chain and cable protection

- Food machinery lubricants

Reliability Products

LE Xamine

Is integral to any successful lubricant reliability program. With consistent, accurate monitoring of the condition of your oil – whether in an engine, gearbox, circulating system or mainline power generation turbine – an oil analysis program can help you improve your bottom line with less lubricant to purchase, fewer parts to keep in inventory, less used lubricant requiring disposal, less labor and less downtime.

Using one of LE’s oil analysis programs enables you to be more efficient with your use of lubricants and reliability tools. LE’s oil analysis monitors oil samples for mechanical, operational and environmental factors that can affect equipment and oil life.

You can be confident you’re testing with a company that knows lubricants and knows your equipment. LE has oil analysis solutions to service your specific business needs, including Xamine™ Oil Analysis for engines or industrial equipment, and Xamine™ Turbine Oil Analysis for mainline turbines. After consultation, we can recommend the right program to suit your needs.

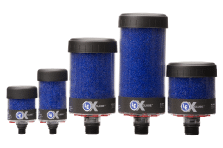

LE Xclude

Breathers are the first line of defence against contamination. The desiccant breather replaces the standard dust cap or OEM breather cap on equipment, offering better filtration to protect against even the smallest particulates that destroy the effectiveness of your machinery and cause downtime and costly repairs.

As air is drawn into equipment through the breather, the layered desiccant filter elements remove particulate while the desiccant beads strip harmful moisture while in service or during shut-down, the desiccant beads.

LE Xtract

Visual oil inspection products are designed for easy installation on almost all lubricating machinery oil reservoirs. Constructed of durable acrylic, they withstand most petroleum products to remain crystal clear and functional for years. LE provides service and solutions to maintenance and lubrication management personnel in many industries, including chemical and petrochemical processes, food and beverage processes, pulp and paper mills, power generation, mining, municipal water and waste treatment industries, along with others that use large equipment in their processes.

LE Xpel

is a lubrication management system that establishes best practices throughout your facility. Every step is colour-coded to eliminate risk and human error, simplifying maintenance and extending the life of your equipment.

Colour-coded bulk storage keeps your storage area neat, safe and clean. Modular and scalable, the unit can be configured to your exact needs and arrives preassembled for easy setup. Each tank has its own pump and filter to prevent cross-contamination.

Precise-pour transfer containers feature push-button air intake valves, quick-twist spouts and ergonomic manual pumps for fast, smooth pouring and pumping. They come in a range of sizes with interchangeable, colour-coded lids.

LE Xpel Poly Tank Solution

Stackable storage and handling systems are designed to reduce your total fluid expenses, maximize floor space, and provide safe and efficient storage for a vast number of bulk fluids including oils, lubricants, hydraulic fluids, ATF, anti-freeze and DEF.

A stackable storage tank system will handle all of your bulk fluids so that you can eliminate the hassles and clutter of packaged goods and drums while lowering your overall fluid expenses by enabling bulk oil delivery.

LE Xport

Clear up greasing mistakes with Xport™ Clear Grease Guns. While traditional grease guns do not allow the maintenance operator to see what’s inside. Place the wrong grease into an application or – even worse – mix two greases that are not compatible, and you could cause catastrophic equipment failure costing time and money to correct. It has been estimated that 60 to 80% of bearing failures are lubricant-related, including grease cross-contamination. LE’s Xport™ Clear Grease Guns are a simple, cost-effective solution for eliminating cross-contamination. Much more than just another grease gun, the Clear Grease Gun is an innovative reliability tool that has enabled industrial operations worldwide to eliminate greasing mistakes. It makes a great addition to existing reliability efforts, playing a role in elevating lubrication standards, increasing accountability and raising overall safety awareness.

Viper

The Viper MKII Wire Rope Lubricator will clean and lubricate wire ropes quickly, efficiently and safely. Wire ropes from 8 mm (5/16”) to 165 mm (6-1/2”) in diameter can be automatically greased at speeds up to 2,000 mt/hour.

While other lubricators just coat the surface of the ropes, the unique seal design of the Viper wire rope lubricator means the “wire dwell time” in the pressure chamber is up to 80% longer leading to a fast, efficient wire rope lubrication.

Bijur Delimon

Bijur Delimon International is a global leader in the design and manufacturing of various fluid dispensing products and systems. These systems range from simple single-point grease feeders to complex automatic systems that dispense oil or grease to hundreds of lubrication points. Lubrication products and components for almost any industrial application, including Pumps, Distribution Elements, Controllers and Accessories for the following systems.

Macnaught

Designs and manufactures a wide range of lubrication and fluid transfer equipment including manual and powered grease pumps, oil pumps and guns, fuel pumps, hose reels and flowmeters. RETRACTA Auto-Rewind Reels are backed by an unmatched 10-year limited warranty. The RETRACTA reel’s success lies in its superior positive latching mechanism. This ensures latching functionality regardless of orientation, and, with its 180° rotation and lockable wall or overhead mounting bracket, the RETRACTA reel can be mounted in any position.

Contact Us

Contact Davis Controls today about our state-of-the-art products and experience our expert application advice and reliable service!

CONTACT US