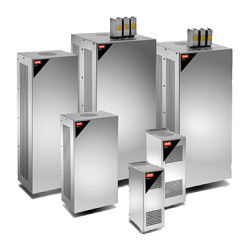

VLT® Drives – Dedicated, reliable and user-friendly products that fit your specific application requirements and reduce your total cost of ownership. Danfoss AC drives are independent of motor manufacturers and adapt to any motor technology.

Danfoss offers a wide range of high-performance drives that improve system efficiency and performance across industries. From the Danfoss Variable Frequency Drive to the Danfoss Frequency Drive, Danfoss Aqua Drive, Danfoss Vacon Drives, and Danfoss Ac Drive, each solution is tailored to meet the unique needs of your application.

Low voltage drives, Decentral drives, Motion drives and Gear Motors and Soft starters.

Gain a competitive edge with Danfoss AC Drives

The fourth Industrial Revolution, or Industry 4.0, builds on the progress of automation by introducing elements of interconnectivity, data acquisition, machine learning and intelligent application of analytics. AC drives play an important and powerful part in this transition by being the first point of interaction between sensors from the process, the motor in operation and then communicating this information to a central control location.

Energy savings – Energy savings are tied to the technology and the fact that applications need less energy when idle or operating with partial loads. Danfoss drives do the trick.

Fully automated operation – Danfoss drives enable a facility to increase its automation capabilities. Not every application is the same across all industries, but with customized programming, customers can determine what parameters are essential to their specific needs.

100% full load factory tested – Having received an order – a drive specified by the customer – Danfoss builds it and tests it against real motors before shipping.

A breakthrough in drive technology: VLT® with Condition based monitoring

Danfoss VLT® Drives with built-in intelligence can now monitor the condition of motors and applications, allowing you to detect deviations in baseline parameters early in order to proactively intervene before the deviations have a negative impact on your operations.

DrivePro® Site Assessments

With a DrivePro® Site Assessment, our well-trained experts will assess your facility’s VFD installed base, review your assets based on visual conditions, and evaluate the life-cycle stage of your individual assets. Based on this assessment you will receive a tailored service solution which will enable you to optimize up-time and reduce maintenance costs.

Site assessments may be done virtually or in person at your facility using digital tools.

VLT® AQUA Drive FC 202

Built-in intelligence to keep your system running

Intelligence embedded in the VLT® AQUA Drive FC 202 automatically defines baseline parameters for water and wastewater applications, at all speeds and real-life operating cycles. In the event an issue is detected, Digital Cascade Control Hot Swap technology combined with backup master functionality ensures reliable, stable and easy operation to help you stay up and running.

In addition to the features provided by the VLT AQUA Drive, Danfoss offers DrivePro®-tection which provides up to a 6-year on-site warranty to ensure the continued operation of your drive.

VLT® AutomationDrive EZ FC 321

Flexible and expandable: With a flexible modular design, the AutomationDrive EZ FC 321 is packed with standard features which can be expanded with plug-and-play options with additional features and fieldbuses. Safe Torque-Off is a standard safety feature that can be applied through hardwired safety.

Printed circuit board protection: Drives up to 100 HP conform to class 3C2 (IEC 60721-3-3) as standard. Drives above 100 HP come standard with 3C3.

Robust and reliable: VLT® AutomationDrive EZ FC 321 is a proven performer in all industrial environments and grid voltages, including 690 V. Enclosures are available up to NEMA 4X (depending on model) and integrated DC chokes and RFI filters in all models protect installations by minimizing harmonic distortion and electromagnetic interferences. All drives are tested at full load before leaving the factory.

Easy set up and commissioning: The VLT® AutomationDrive EZ FC 321 is easy to set up and operate via the user-friendly graphical control panel, requires minimal maintenance, and delivers a market leading control solution which provides a fast return on investment with a highly competitive cost of ownership.

Smart Start wizard:Includes groups for several of the most common applications, including conveyors, pumps and fans, and setup with mechanical brake. With the settings to run applications already in place, you can get your machine up and running faster, increasing your productivity.

iC7-Automation Frequency Converter

Input Voltage 280 – 500 V AC (+10% -15%)

The iC7 Series of intelligent AC drives puts the power of compactness and integrated intelligence in your hands, so you can boost machine performance in new ways.

With the best heat management available anywhere, this drive delivers high torque performance in a small footprint, so you can get much more power into small spaces.

Integrated intelligence enables the drive to function as your most powerful sensor meaning you can regulate your process highly efficiently, saving money by reducing external devices. For quick and trouble-free system integration the frequency converter comes with built-in EMC and harmonic filters.

VACON® NXS

The VACON® NXS is an AC drive for heavy use in machines, buildings and all branches of industry. Typical applications include pumps, multi-pump, conveyors and compressors.

The VACON® NXS features a modular design that offers several advantages for any installation. The robust power module is designed for efficient cooling and features a snap-on fan unit that is simple to remove and replace.

The control box, found on every VACON® NXS drive is designed to safely separate the control terminals from the power terminals. This modular design also allows the VACON® NXS to be field upgraded to a UL TYPE 12/IP55 enclosure without the need to increase the footprint of the drive.

- Easy to use display panel

- Interactive programming with Start-Up Wizard

- Versatile All-in-One Package

- PID controller and PFC for 1-5 pumps

- Special applications available (water application package, high speed, etc.)

- Five slots for control boards (2 basic boards and 3 option boards)

- High switching frequency, low noise

- Steady state speed error < 1%

- Low torque ripple

- Starting torque > 200%, depending on AC drive sizing

- Suitable for multi-motor applications

Optimum process control and energy efficiency for a wide variety of electric-motor-driven applications in a diverse range of industries, including liquid and air-cooled drives. The portfolio covers a power range of 0.25 kW – 5.3 MW.

One drive for a wide range of applications

VACON® 100 Industrial Drive is full of features and dedicated to a wide range of constant power/torque applications. The easy-to-use and robust motor controls improve the reliability and efficiency of all AC motor types, including induction, permanent magnet and synchronous reluctance motors.

Integrated RS485 and Ethernet interfaces support all major industrial protocols making the VACON® 100 Industrial drive easy to incorporate into all major control systems. The built-in PLC functionality enables the integration of new functionality into the drive. Functional safety is improved with Safe Torque Off, which prevents the motor from generating torque on the motor shaft, Safe Stop 1 and ATEX-certified motor over-temperature protection.

The wall-mountable drive modules are easy to install and operate, and the enclosed drives are provided with a wide range of integrated options.

HARMONIC FILTERS, DVDT FILTERS, REACTORS (LINE AND LOAD)

Power quality management requirements differ significantly by utility, industry, application and country. Consider power quality and filter products for both input (line-side) and output (load-side) of variable frequency drives (VFDs) and power conversion equipment. These components represent strategic elements of power quality.

Solutions include:

- Power Quality Filters

- EMC filters

- Variable Speed Drive Braking Resistors.

VLT® Advanced Harmonic Filter AHF 005 and AHF 010

- Optimized harmonic performance for VLT® drives rated up to 250 kW

- A patented technique reduces THD levels in the mains network to less than 5–10%

- Perfect match for industrial automation, highly dynamic applications and safety installations

- Line voltage and filter current: 3 x 380/400/500/600/690 V…10-480 A*

* Achieve higher ratings by connecting in parallel.

VLT® dU/dt Filter MCC 102

- Reduces the dU/dt values on the motor terminal phase-to-phase voltage

- Positioned between the AC drive and the motor to eliminate very fast voltage changes

- The motor terminal phase-to-phase voltage is still pulse shaped but its dU/dt values are reduced

- Reduces stress on the motor’s insulation and is recommended in applications with older motors, aggressive environments or frequent braking which cause increased DC link voltage

- VLT® FC series family look

- Line voltage and filter current: 3 x 200 – 690 V … 15-880 A*

* For higher power ratings, combine multiple modules.

VLT® Common Mode Filter MCC 105

- Positioned between the AC drive and the motor

- They are nano-crystalline cores that mitigate high frequency noise in the motor cable (shielded or unshielded) and reduce bearing currents in the motor

- Extends motor bearing lifetime

- Can be combined with dU/dt and sine-wave filters

- Reduces radiated emissions from the motor cable

- Reduces electromagnetic interference

- Easy to install – no adjustments necessary

- Oval shaped – allows mounting inside the frequency converter enclosure or motor terminal box

- Line voltage and filter current: 3 x 380-690 V 10-480 A

The Right VFD Cable Can Prevent Premature Motor Failure

VFD outputs can cause a non-VFD cable to broadcast noise that can affect nearby devices. Commonly used alternative products such as unshielded tray cables or THHN wire are not suited for this application and can cause your motors to fail prematurely.

Ozone will degrade PVC and can lead to cable failure. For this reason, most VFD manufacturers recommend using cable with XPLE insulation with a minimum 20mil thickness. XPLE has a higher corona inception voltage and is not as likely to fail as a PVC insulated cable.

For any motor supply application involving a Variable Frequency Drive, we recommend LUTZE DRIVEFLEX® cables with XLPE insulation. These cables have very low capacitance, high impedance and high voltage breakthrough resistance.

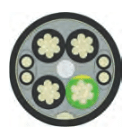

Motor, VFD, Servo and Feedback Cables

LUTZE offers a variety of motor, servo and feedback cables to address the specific requirements of motor and VFD applications. The product range consists of flexible and high flexing cables for system specific as well as universal applications. Advantageous features are improved electrical characteristics such as low capacitance and high impedance.

DRIVEFLEX® VFD cables are designed to meet the unique electrical challenges in VFD and Servo applications. All DRIVEFLEX® VFD cables use a special formulation of cross-linked polyethylene insulation (XLPE), providing excellent electrical characteristics while maintaining the utmost flexibility for a drive cable.

- Thermoset insulation designed to cope with power distortions in VFD applications

- UL listed type “Flexible VFD Servo Cable, Flexible Motor Supply Cable”

- Superior electrical values for VFD applications

- Flexible for easy routing and installation

LUTZE DRIVEFLEX ® XLPE (C) PVC, Shielded

Flexible VFD Cable XHHW-2 for Stationary Applications

Dual-shielded motor supply cable to connect power to 3-phase motors, VFDs and servo drives

- Cable design for harsh industrial environments and operating conditions with high noise levels

- Thermoset XLPE insulation offering superior overload and short-circuit temperature

- Type XHHW-2 insulation offering smaller ODs for general VFD applications

- Compliant with NFPA 79 requirements

- TC-ER-JP for use with cable trays without conduit, which can reduce installation costs in industrial environments

- WTTC – wind turbine tray cable rating for use in wind power generation

- Dry, damp or wet conditions

- Flexible XLPE conductor design

- Reduced cable ODs

- High insulation resistance

- Low capacitance cable

- Effective dual layer shield for EMC compliance

- Oil resistant jacket designed for easy stripping

- Non-wicking fillers

- Ecolab certified resistance to common cleaning agents and chemicals used in food and beverage washdown procedures

- Crush impact resistant

- Gas/vapour-tight sheath per UL 1277

- Sunlight resistant

- Flame retardant

- Direct burial

- Talc and silicone free

LUTZE DRIVEFLEX® XLPE (C) 2 TSP PVC, Shielded

Flexible Composite VFD Cable with two Control Pairs for Stationary Applications

Dual-shielded motor supply cable to connect power to 3-phase motors, VFDs and servo drives

- Cable design for harsh industrial environments and operating conditions with high noise levels

- Thermoset XLPE insulation offering superior overload and short-circuit temperature

- Increased wall thickness insulation type RHW-2, offering lower capacitance and higher impedance making it ideal for applications with high voltage spikes and long cable runs

- Compliant with NFPA 79 requirements

- TC-ER-JP for use with cable trays without conduit, which can reduce installation costs in industrial environments

- WTTC – wind turbine tray cable rating for use in wind power generation

- Dry, damp or wet conditions

- Flexible XLPE conductor design

- High insulation resistance

- Low capacitance cable

- Effective dual layer shield for EMC compliance

- Oil resistant jacket designed for easy stripping

- Non-wicking fillers

- Ecolab certified resistance to common cleaning agents and chemicals used in food and beverage washdown procedures

- Crush impact resistant

- Gas/vapour-tight sheath per UL 1277

- Sunlight resistant

- Flame retardant

- Direct burial

- Talc and silicone free